Our focus is on designing the best boats

As part of this on-going process we continually get data from our built boats to verify our design theories. Our boats become full scale tank test models and we use the data derived from each and every boat to develop the designs further.

We also spend a lot of time and money on research and development in a quest to create the best boats.

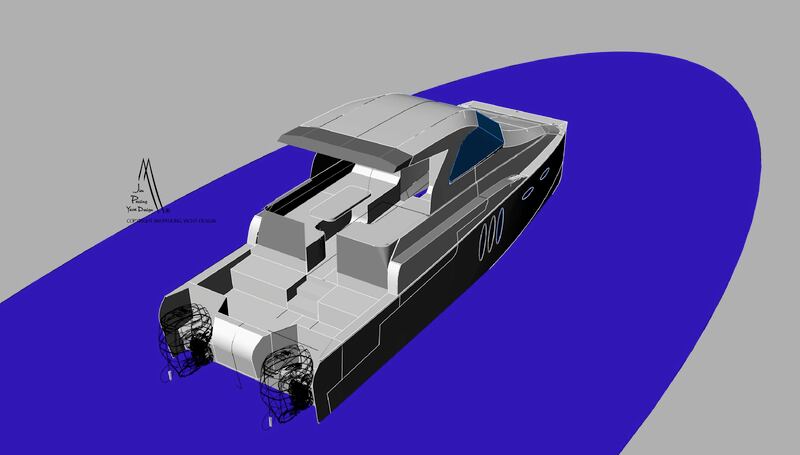

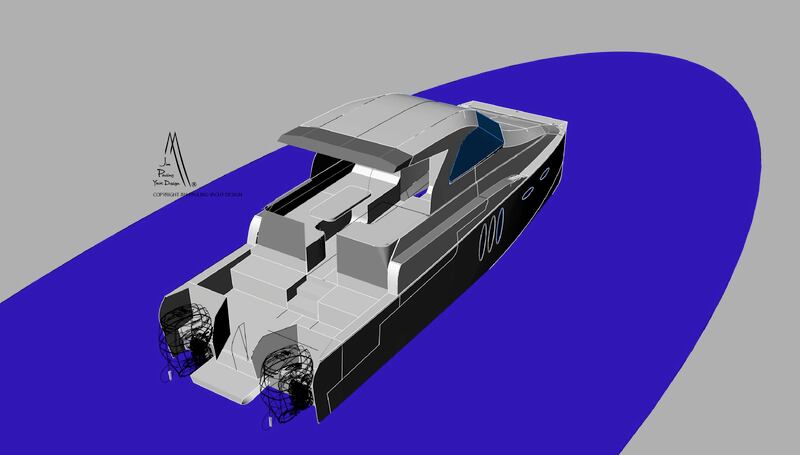

The Rêvo 442 is an example of this development and after many years of research and development we are conducting final testing on this design. The figures and all-round performance we have achieved are very pleasing with even more advancements to come.

We also spend a lot of time and money on research and development in a quest to create the best boats.

The Rêvo 442 is an example of this development and after many years of research and development we are conducting final testing on this design. The figures and all-round performance we have achieved are very pleasing with even more advancements to come.

Fabricated polyethylene boat development in New Zealand

Some years ago I was asked by a company in Auckland if I could design a boat using high molecular weight polyethylene (HMWPE). This was a product they were using to build skip bins. After procuring the material specs and conducting some engineering calculations I concluded that not only could it be used to build a boat but that it would in fact be very good for certain types of boats. Unfortunately as often happens with companies that have little to offer, that company was found to be completely unsatisfactory to deal with and although I did try to teach them how to build boats, their lack of skills and expertise and inability to to comprehend the details of boat design, engineering and construction meant that I severed ties with them altogether.

Anyway at the time I had designed a 6 metre longboat for a customer in Auckland to be built in ply and glass but with the cost of fairing and painting it just wasn't financially feasible to build. This design did however become the the base design for our first fabricated (welded) polyethylene boat or what I call NRP (Non Reinforced Plastic). I designed and engineered the boat and helped the company assemble the first boat. At that stage the detail of the welding was left to them and it was largely based around tacking it together as the sheets lay and welding it off. While the welding detail left a lot to be desired the boat was tested hard and held up well. This absolutely proved that the product was indeed viable and I set about developing my understanding of the welding and conducted tests to improve the welded joints. Some time later Brett Patterson who was the marketing manager for Boating NZ approached me having knowledge of the first boat and realised it would be perfect for a salt water fly fishing venture he had in mind. This gave me the opportunity to take the development of the first boat to a new level and gave me the opportunity to put one into survey, thereby proving the fabrication method. This is was how the Revo 601 Superfly came about. Developing a boat that was specifically designed for this type of fishing, could operate efficiently so it could return a profit on the investment and being the first fabricated polyethylene boat in New Zealand in survey was a challenging and ambitious project which ended up consuming 500 hours of design work. I built the boat and contracted a company to do the welding. The result was outstanding. The plan was to teach this company to build the boats and did offer them the opportunity to buy the design and own the rights to build the boats but they declined for financial reasons so I decided to produce the boats under my Rêvo Brand. This way we can ensure the product meets our standards worthy of carrying the Revo mark. The boats are built in-house where we have control over key decisions and can control the outcome, this way the customers can rely on and have complete faith in the Revo brand that we have worked so hard for many years to establish. This is how we came to be polyethylene boat manufacturers. During the construction of the first Superfly, I had been pricing an alloy powercat for a customer in Sydney. When it emerged that I lost the job after 3-4 months of preliminary design work and pricing on the cost of a paint job, I decided to offer him a polyethylene version. He asked to see the 601 and flew in from Sydney. After looking at the 601 Superfly for about a minute he turned to me and said "this is what I want" Once again this was a very specific design which had to meet a 300mm draft requirement in loaded condition and a tight budget. I had to develop a new way to build the boat to keep it light enough but strong enough to meet this draft requirement. That was where 30 years of boat building experience across a wide range of building mediums came to the fore. This boat has been the catalyst for on-going requests for more fabricated polyethylene boats including one of our alloy builders who after seeing the 742 under construction decided that he wanted to build in plastic now instead of alloy. Other notable projects include five polyethylene jet boats to be built, a 12 metre jet powered monohull planing boat, plus a preliminary design for a 45 foot offshore sailing cat. While it can be challenging from a design and engineering perspective, it is a pleasurable way to build a boat and the finished product is very pleasant to be aboard. It could well be worth consideration for your next boat. |

|

Rêvo 651 SportflyThis was a custom design and build for a customer that fished aboard the Rêvo Superfly boats and enjoyed the experience. He wanted a boat for fishing further offshore but easy one man beach launching capabilities with the ability to dive and sport fish with his sons. After I did some design reviewes I settled on a 6.5 metre to maximise the boat for his desired fishing area while still making it easy to handle and efficient to operate to fill his needs. This boat is part of my on-going development of the NRP boats and was built using a better jig system to make the boat more dimensionally accurate and stable. The result is outstanding. It sits on one of my hull matched alloy trailers to make launching and retrieving as easy as possible and towing is a pleasure. It runs a 90 horsepower outboard and has a 55 litre fuel tank which gives a range of 120 nautical miles. Quite staggering. The video to the right is taken aboard the boat. See how smooth quiet and easy she travels. Just simply so pleasurable to be aboard. |

|

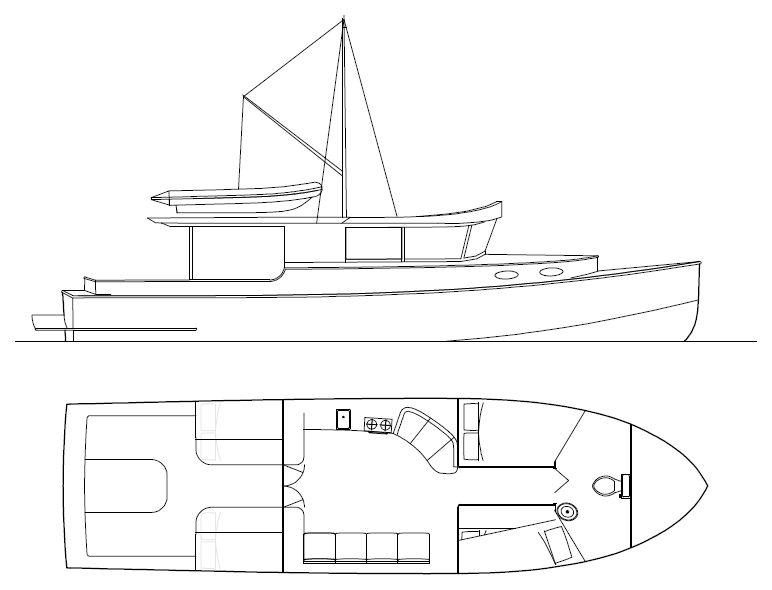

Plastic Cat

This big cat is a 45 footer which was being designed for a customer in alloy, however once he saw the 742 powercat I am building in polyethylene he changed his mind and wanted it in plastic.

The boat is designed for live aboard extended cruising and features many innovative features. The rig is an A-frame with two roller furling headsails for easy short handed sailing and power is twin hydraulic drives off a single motor. There are fore and aft cockpits and the helm is forward in the wheelhouse for unobstructed vision. |

Family launch

This 12 metre launch is to be built in polyethylene, running a 370 horsepower Yanmar and Scott Jet.

It is designed specifically for a family of five to enjoy the Hauraki Gulf and features very shallow draft, eight seats in the cockpit plus a work station/table over the engine. There's a cover over the seated area of the cockpit, with a lounger each side above the seats. The theme is minimalist. This launch sleeps eight. The galley is small as most of the cooking will be done in the cockpit. Set up for weekends out with the family and the annual longer Christmas cruise. Traditional styling with a sizeable tender for sailing, rowing and motoring. The key ingredients are very affordable and very comfortable. |

Rêvo WASP 442LOH 4.4 metres | Displacement 350kg | Horsepower twin 15-30 This 14 foot powercat features two full length bunks. In rough seas we can point the boat in any direction and take our hands off the wheel. The boat is soft riding and incredibly dry We have continued to develop this design over a long period and intend to go into production in fabricated polyethylene. Below are photos of our protoype 442 Powercat under way during sea trials and testing. |

Rêvo Boxt NRP Jet Boat and PLASTIC trailer

|

This is the Rêvo Boxta NRP(plastic) jet boat. Custom designed for a customer who wanted to do more extreme jet boat and liked the toughness of the NRP hull couple with the JPYD superior hull design. The video show the unquestionable results. So good in fact he and is son have ordered a new 4-5 seater V8 version which is currently under construction. Tis new boat is a continuation of the development of the product and is built using a new specialised moulded technique that is improving build times and a real step in quality of the finished product.

The Boxta shown here sits an the first and only plastic street legal trailer in NZ, possibly the world! Designed by Jim Pauling, built by Rêvolution Yachts. The owner loves that trailer almost as much as he loves the Boxta boat. A couple of videos of the boat are shown here so you can see how good she is! |

|

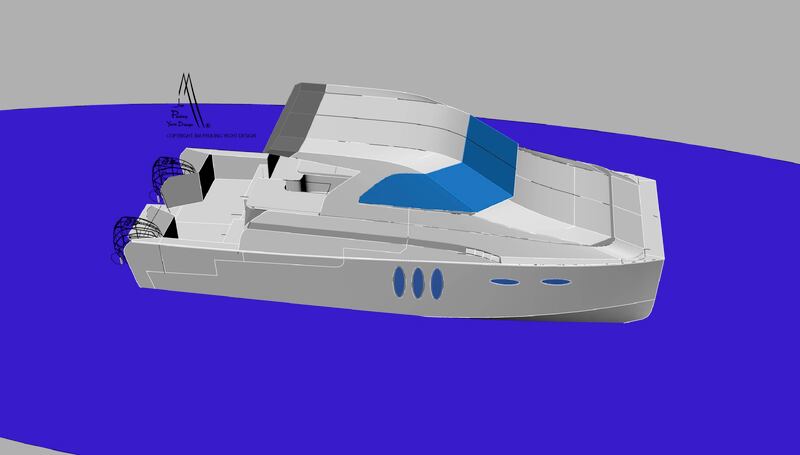

Rêvo 915 Non Reinforced Plastic Powercat

|

This is the latest Non Reinforced Plastic (NRP) powercat to come from Jim Pauling Yacht Design.

It is designed to fit a 30 foot marina berth and features 3 double bunks with dining and lounge area up in the bridge. Head and shower are forward in one hull and the boat has a good sized separated cockpit area. It will run twin Honda 150 outboards for a top speed of 30 knots. This first boat will be built by her owner with our support but we do have more enquiries for completed boats. So much accommodation afforded in the WASP hull form but in a shorter length and yet a hull with great sea keeping qualities and efficiency makes this an extremely economic but capable boat to own. |